So I spent Friday, Saturday, and Sunday working with the Bambu H2D and the Varioshore material from the pervious post to create 1:1 faces for work…

And, I’m close.

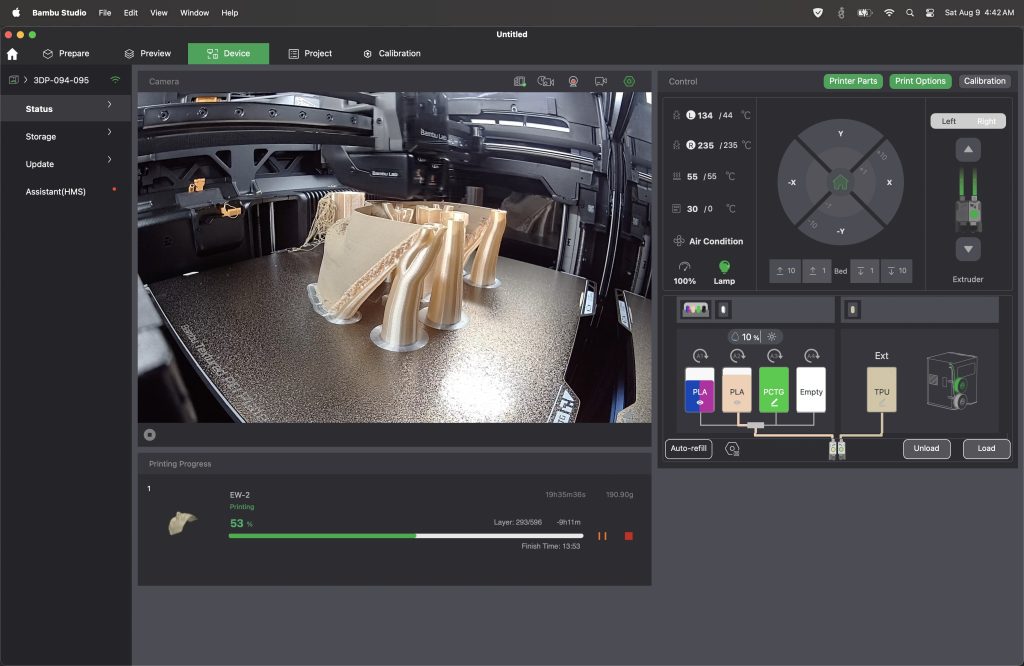

These faces take about 20 hours to print and generally fail when you stop watching like a hawk… So Friday’s print blew up at around 5am Saturday and Saturday’s print blew up at about 2am on Sunday.

Friday’s print was an attempt to print the mask really thin to increase elasticity – so it was about half the thickness of the ones RSO made:

This was unsuccessful. The printer’s biggest enemy is anything moving more than 0.03mm during the 20-ish hours of printing, and the Varioshore when printed super thin (even with a ton of complicated hand-painted supports) just won’t hold still enough.

Saturday’s print spaghetti’d when the printer got confused and just spewed filament everywhere… The cleanup was pretty epic.

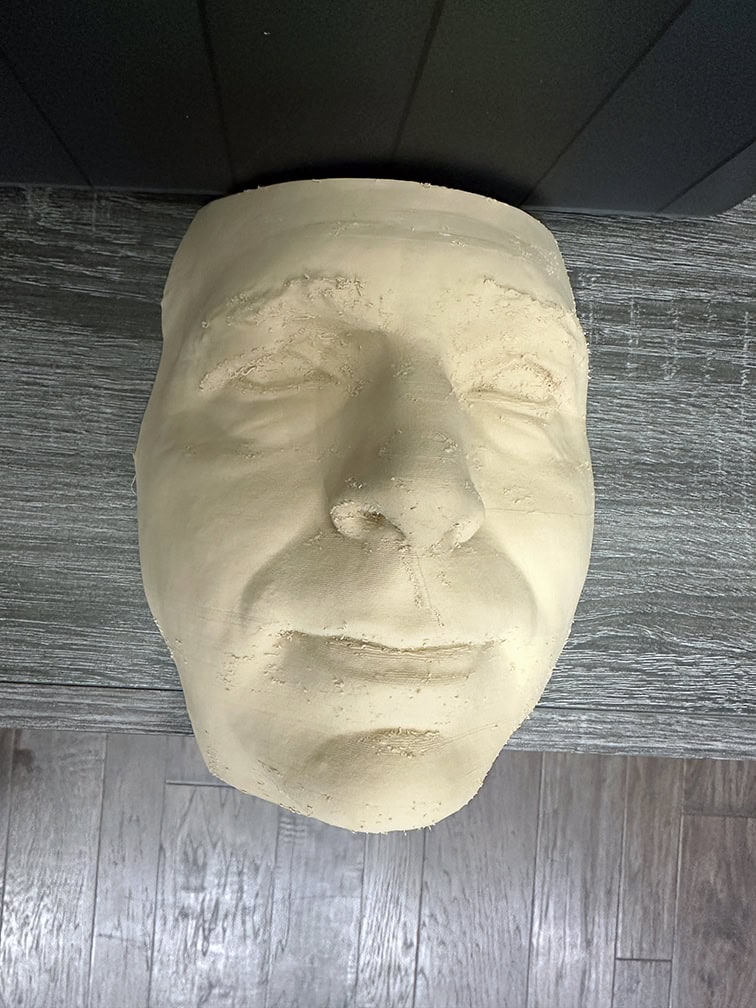

Sunday’s print mostly worked though, and at about 3am this morning I got enough of a positive result to not throw the pinter out of the window. 🙂

The above should be thought of as a proof of concept…

It’s still a bit rough for a few reasons; this Varioshore filament I’m using is a literal sponge and it needs to be printed from a dry box versus sitting out in the air on RSO’s feed contraption – especially when it’s been raining and I like to have the windows open at night…

When the Varioshore gets damp, it creates the rough texture due to the moisture in it flashing to steam at the 250C temperature in the tool head. And a dry box is pretty much what it says on the tin – it’s a sealed spool holder with an integral heater / dehumidifier to keep these super-picky materials happy at 55c and less than 5% humidity.

Without a dry box you can print from, the way you use TPU filaments is to print for a few hours, then put the spool into a desiccant box for 8-10 hours before the next print session… I wanted to iterate faster than this, so the material was left out all weekend and the rough texture was to be expected.

Yesterday I picked up a dry box with a feed port – Microcenter to the rescue – so that takes care of that issue for the next print.

There was also problem with the layer seaming that I didn’t know about until this was about half done, which is what caused a few imperfection like that line under the nose – but hey, chicks dig scars. I found the seam control options in the slicing software, so I can manually move them all the the back-side of the mask for the next print.

While researching solutions to all of the problems I was having, I also discovered a new material that I will try for these; the Varioshore has a shore hardness of about 55 in optimal conditions – the masks so far are probably shore 60-65 though because we can’t reach optimal conditions. But, while that creates the soft-touch and flexibility, the Varishore isn’t very elastic.

The new material is a shore 60, similar to what we’re getting now out of Varioshore, but is also like 500x more elastic than Varioshore: https://recreus.com/en-en/products/filaflex-60a?variant=45921624555779

I’ll order a spool Friday and give it a whirl when it gets here. It will require some modifications to the printer to decrease the feed pressure at the tool head, so that will be interesting.

Anyway, that’s where I am currently. I’m going to go take a nap for a few hours as the last few nights have been punctuated by printer things every few hours and I’m exhausted.

Leave a Reply